Semester 02 Moss Carpet

Introduction

08 Feb 2023

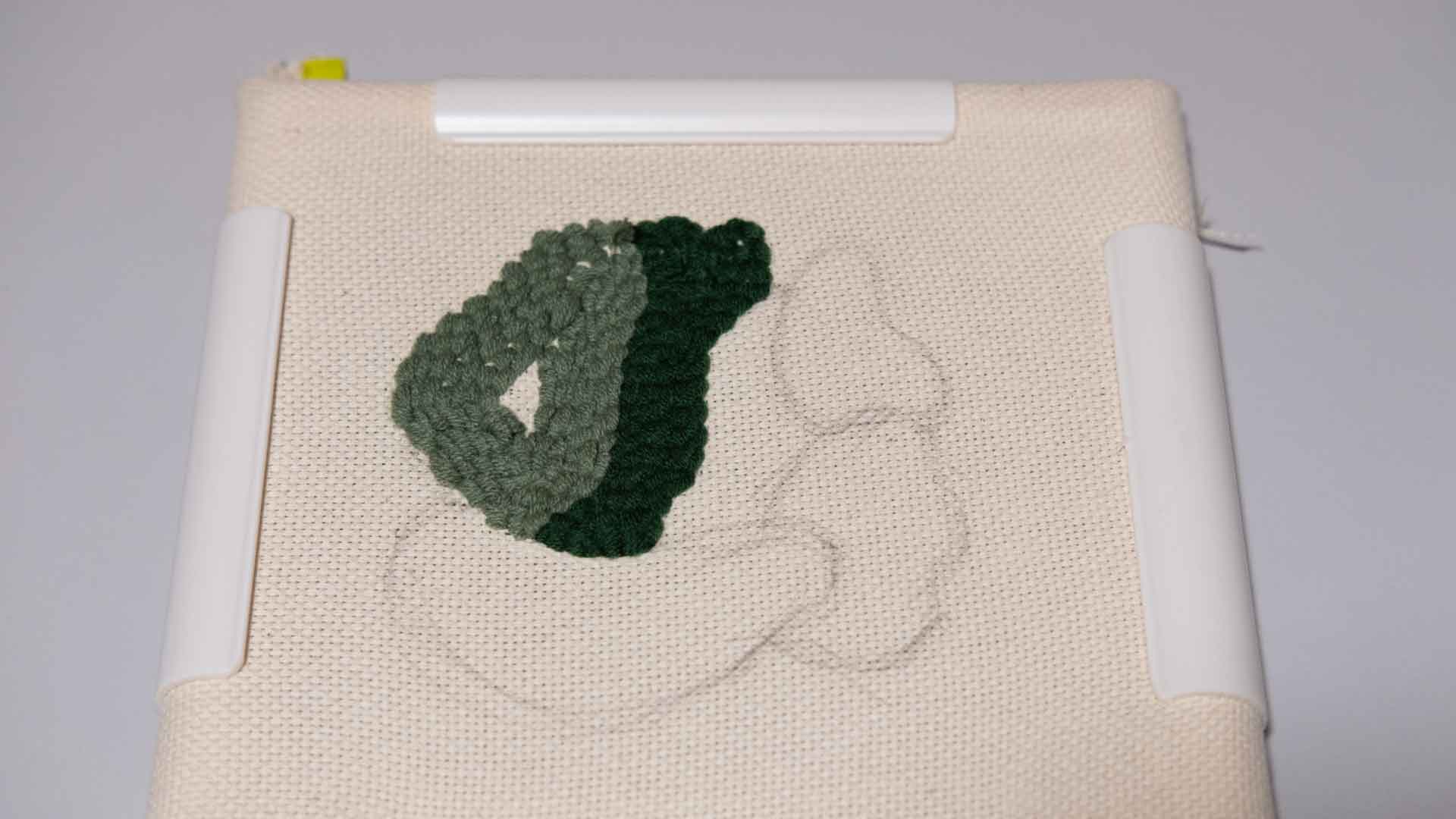

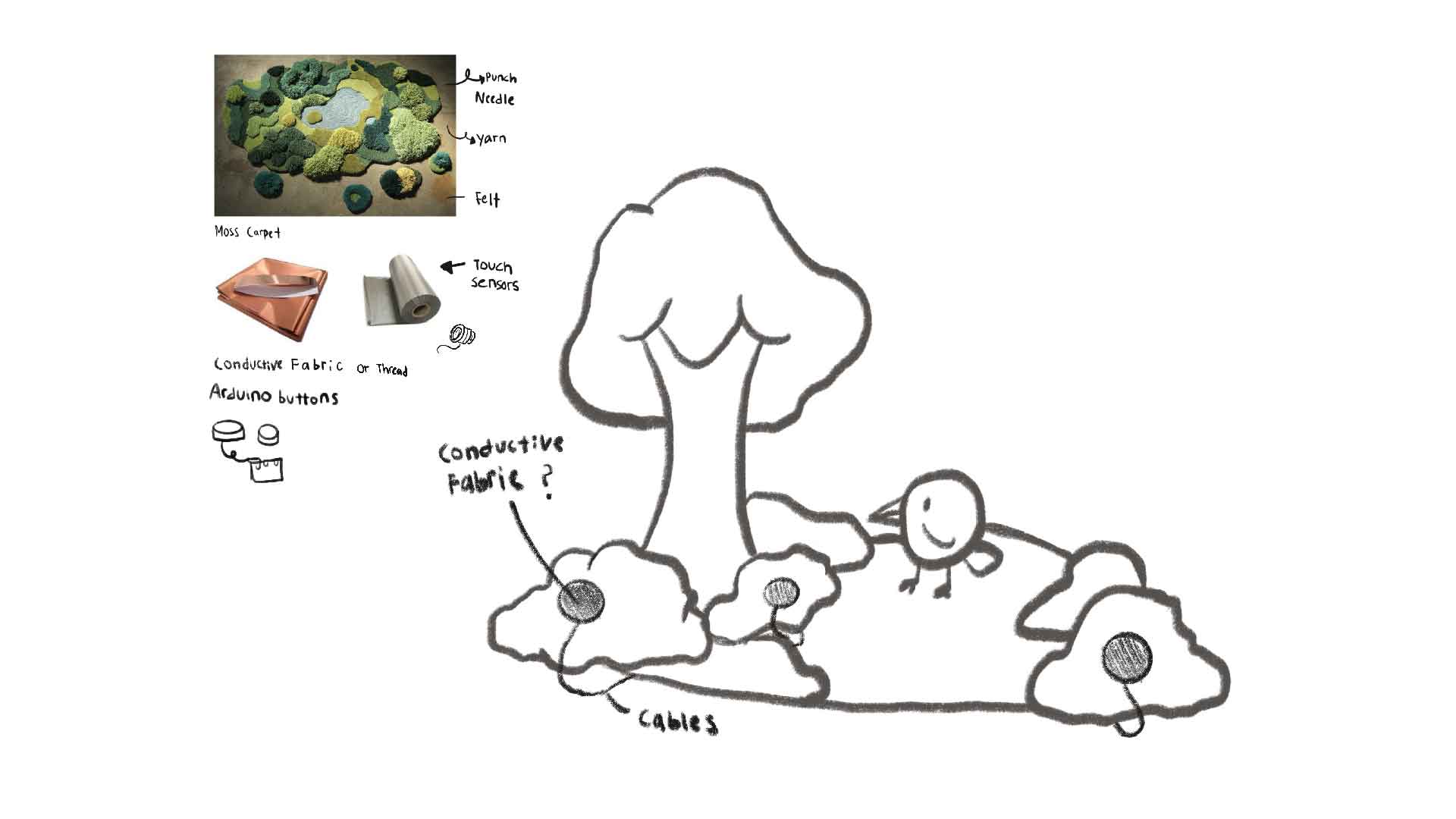

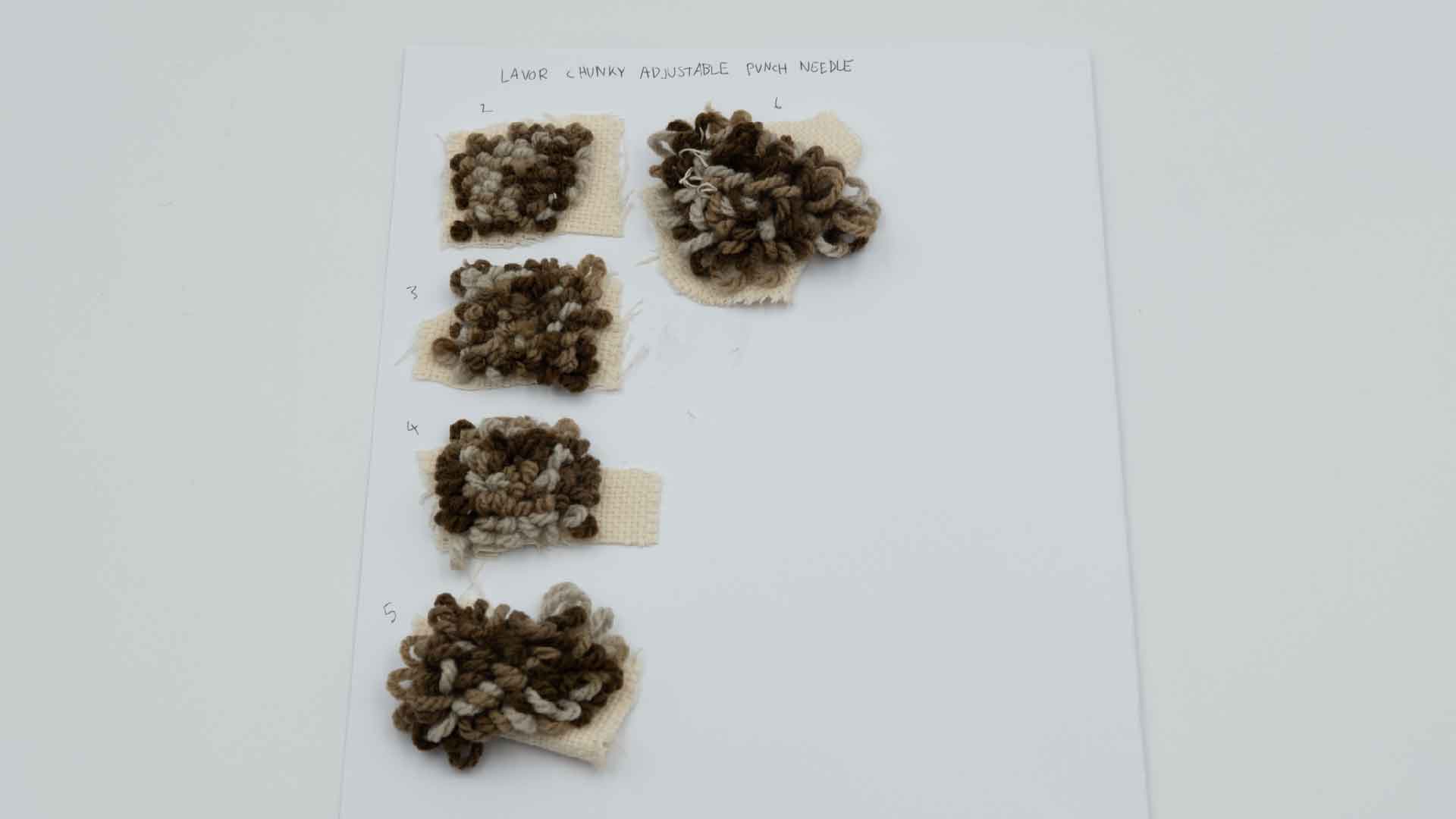

In order to test the prototype, I had to make

test swatches, as it had been a while since I

used a punch needle.

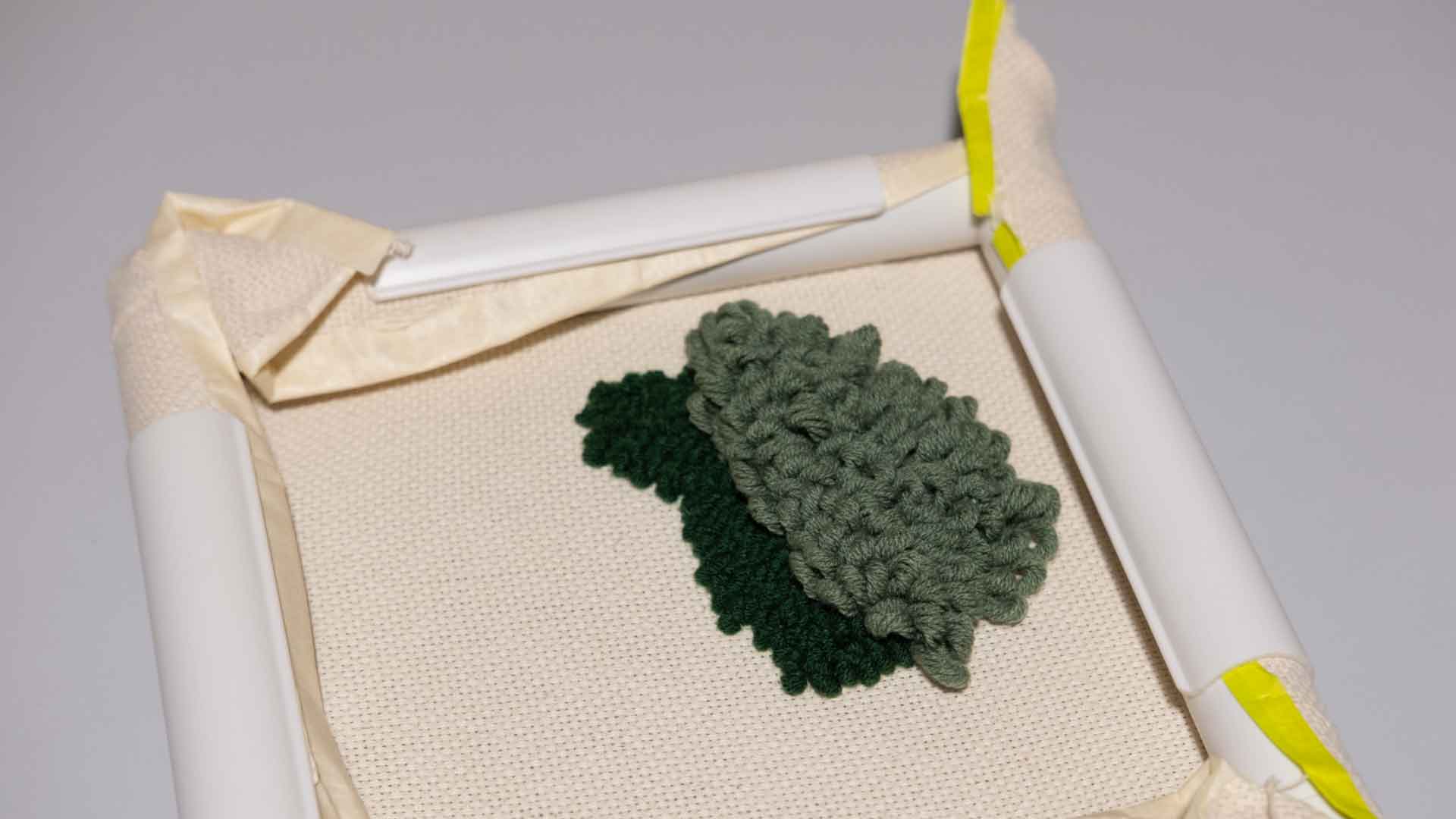

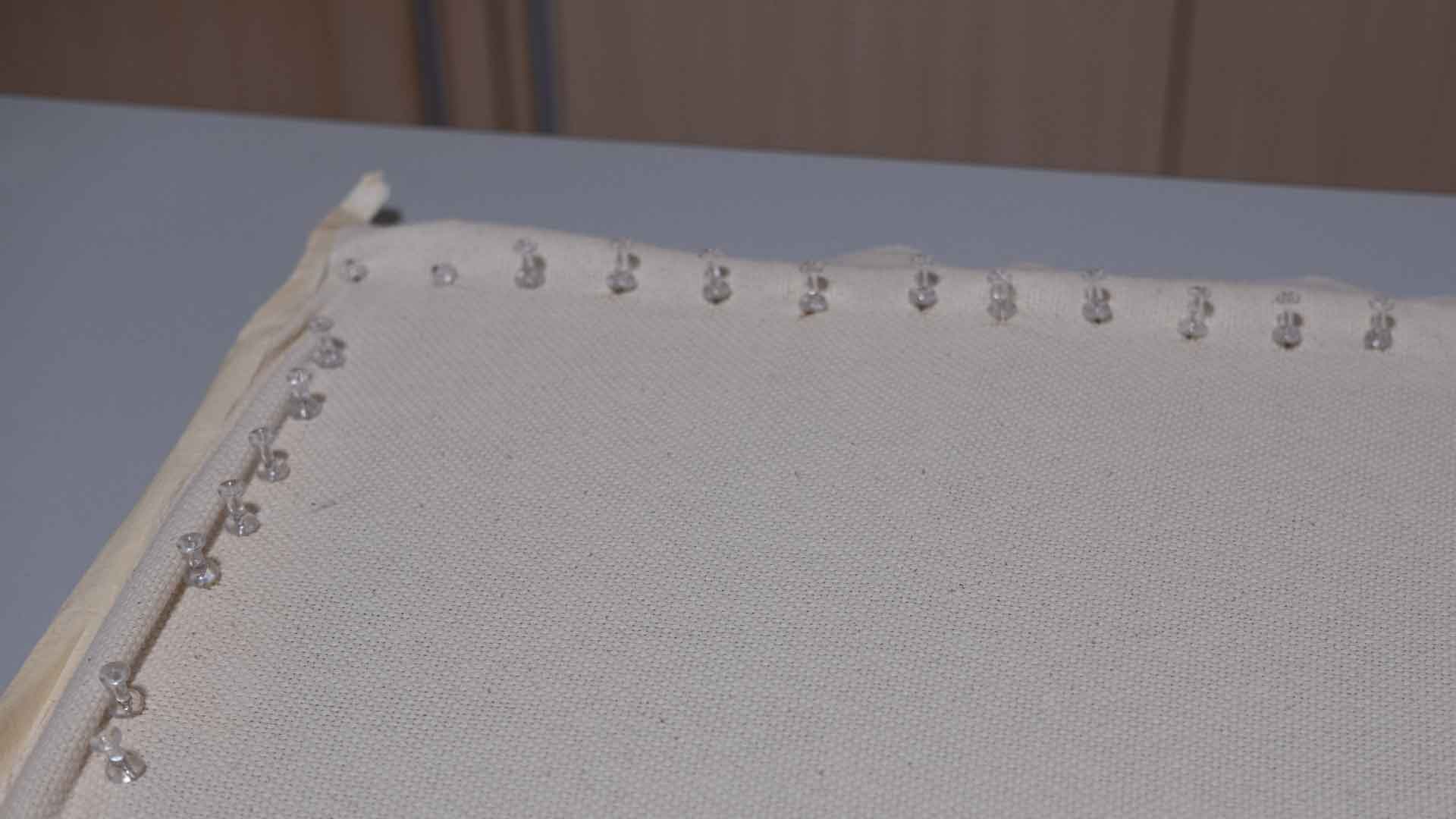

It was difficult at first because my stitches kept coming out because I did not stretch the fabric enough. I prepared a swatch guide made with the different needle sizes to help me determine which needle size to use.

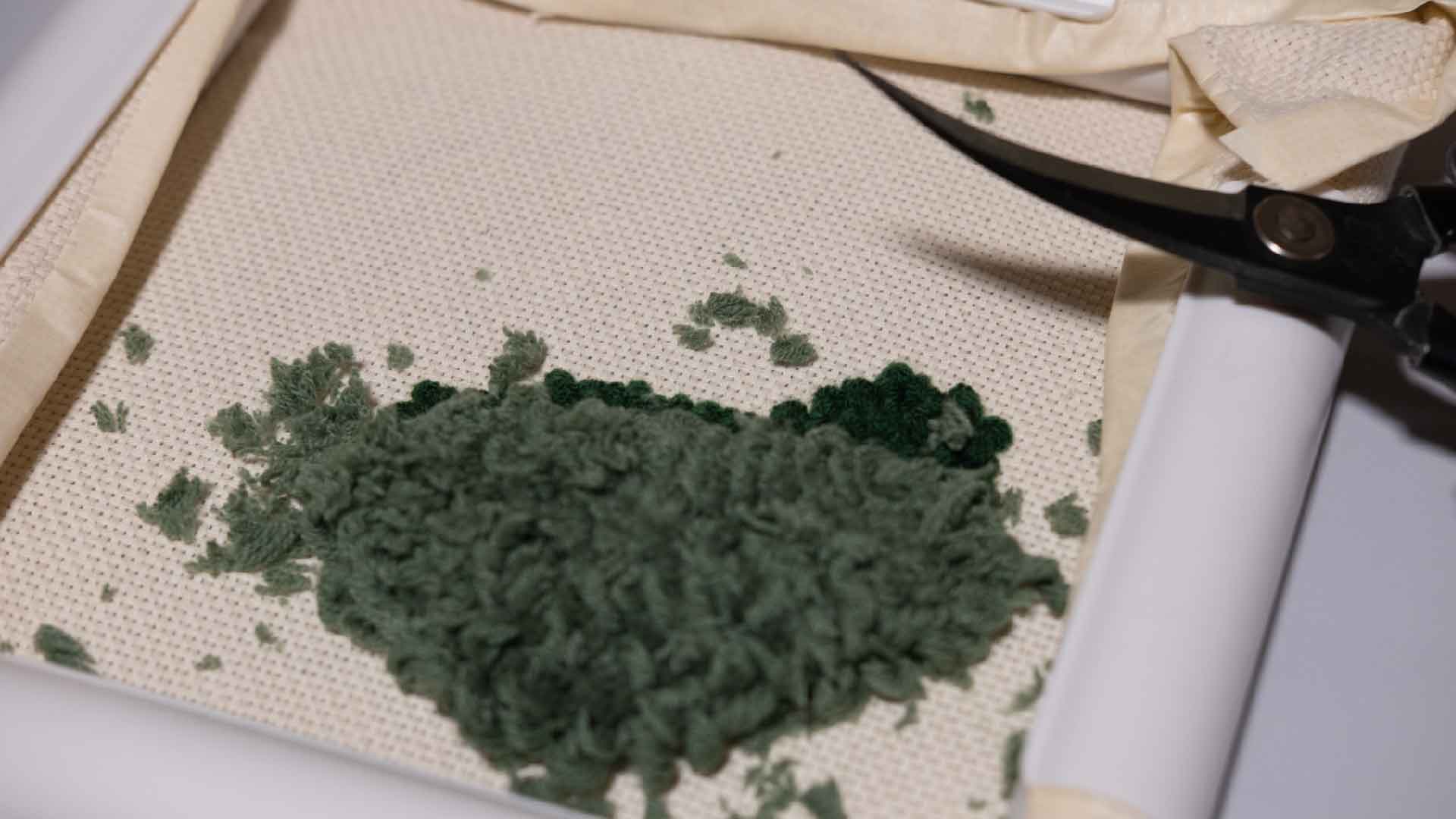

It was difficult to use the thicker needles since they create larger holes in the fabric, which can cause your stitches to loosen. I used scissors to trim the loop piles to create moss textures.

Materials

Yarn

Tools

Punch Needle

Needle

Scissors

Monks Cloth

Swatch Guide

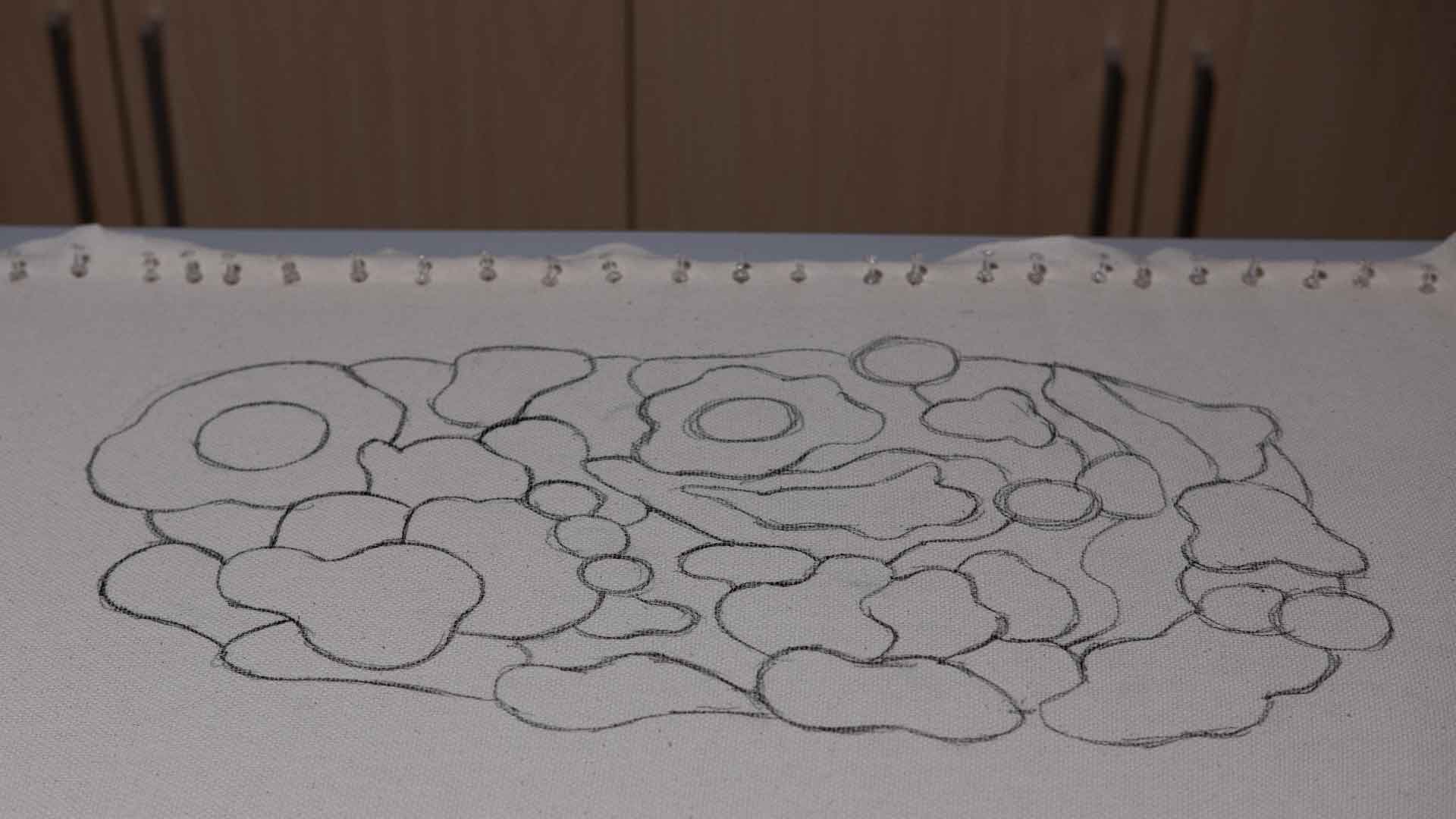

Prototype Process

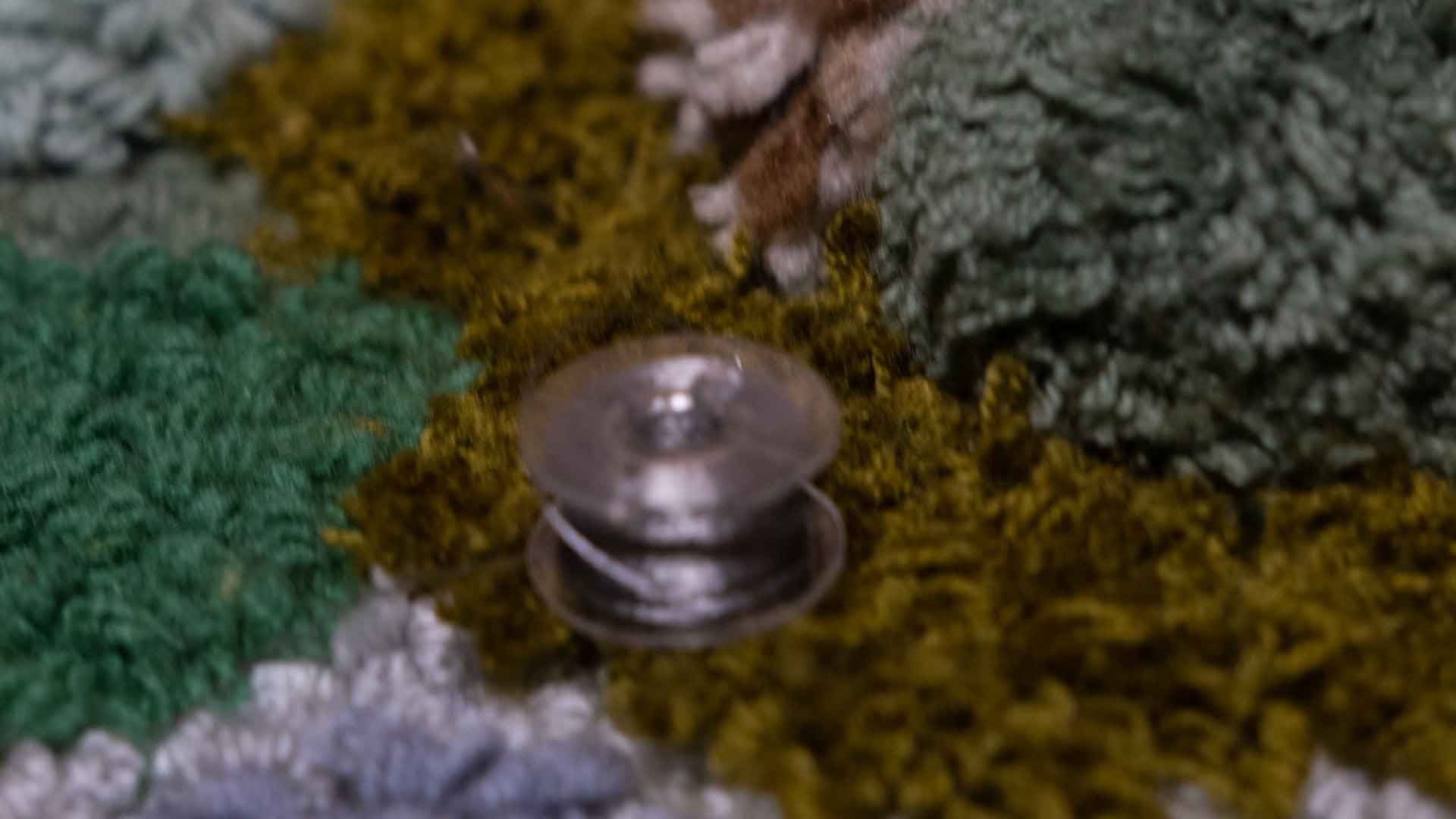

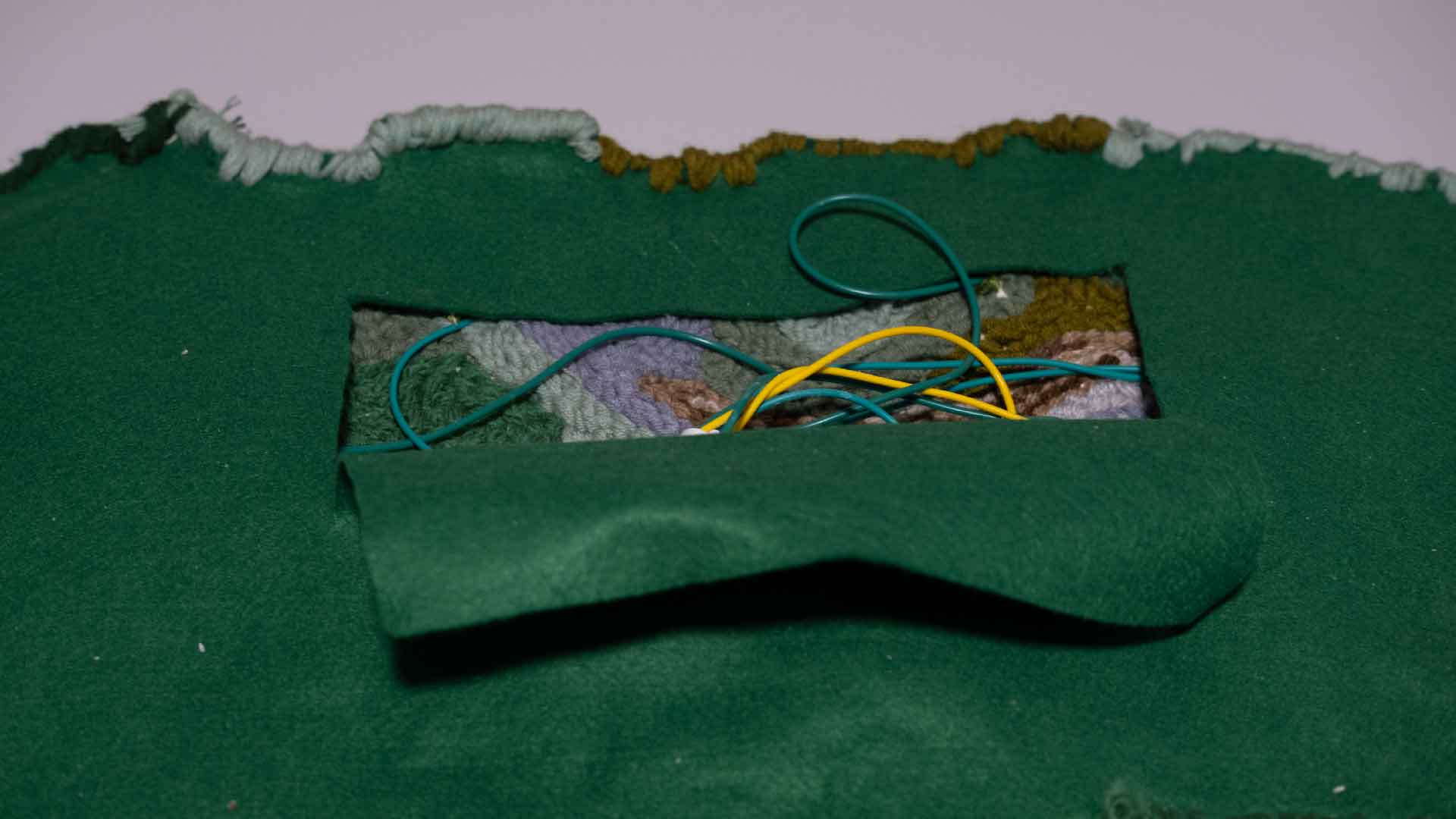

Conductive Wires

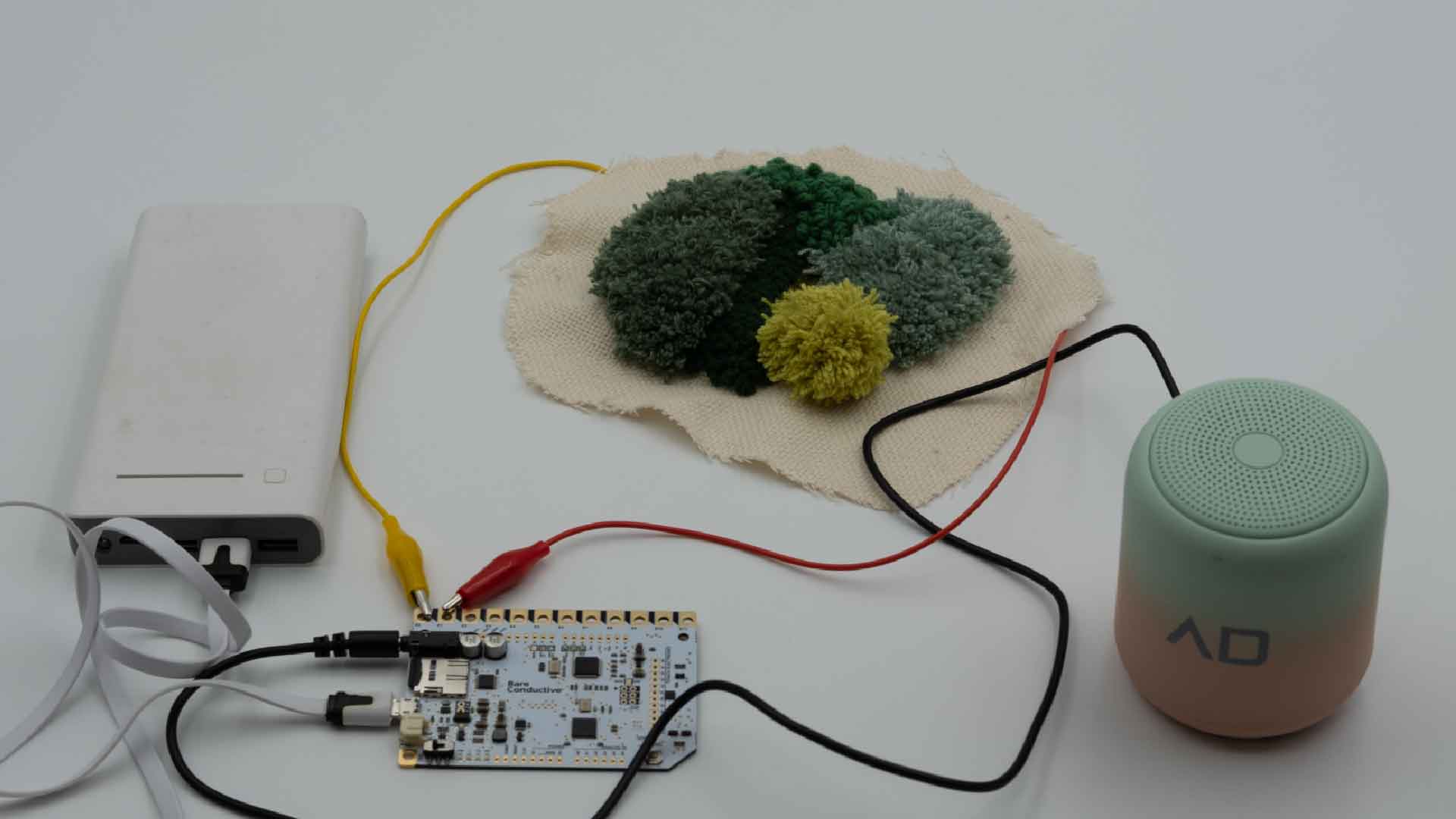

As the yarn is very thick, it was difficult to sew in the cables. My first attempt did not succeed because the copper wires were much shorter than the yarn.

The next time, I will use conductive thread as it is much thinner than copper wires and may be more suitable for this prototype.

Prototype Photos

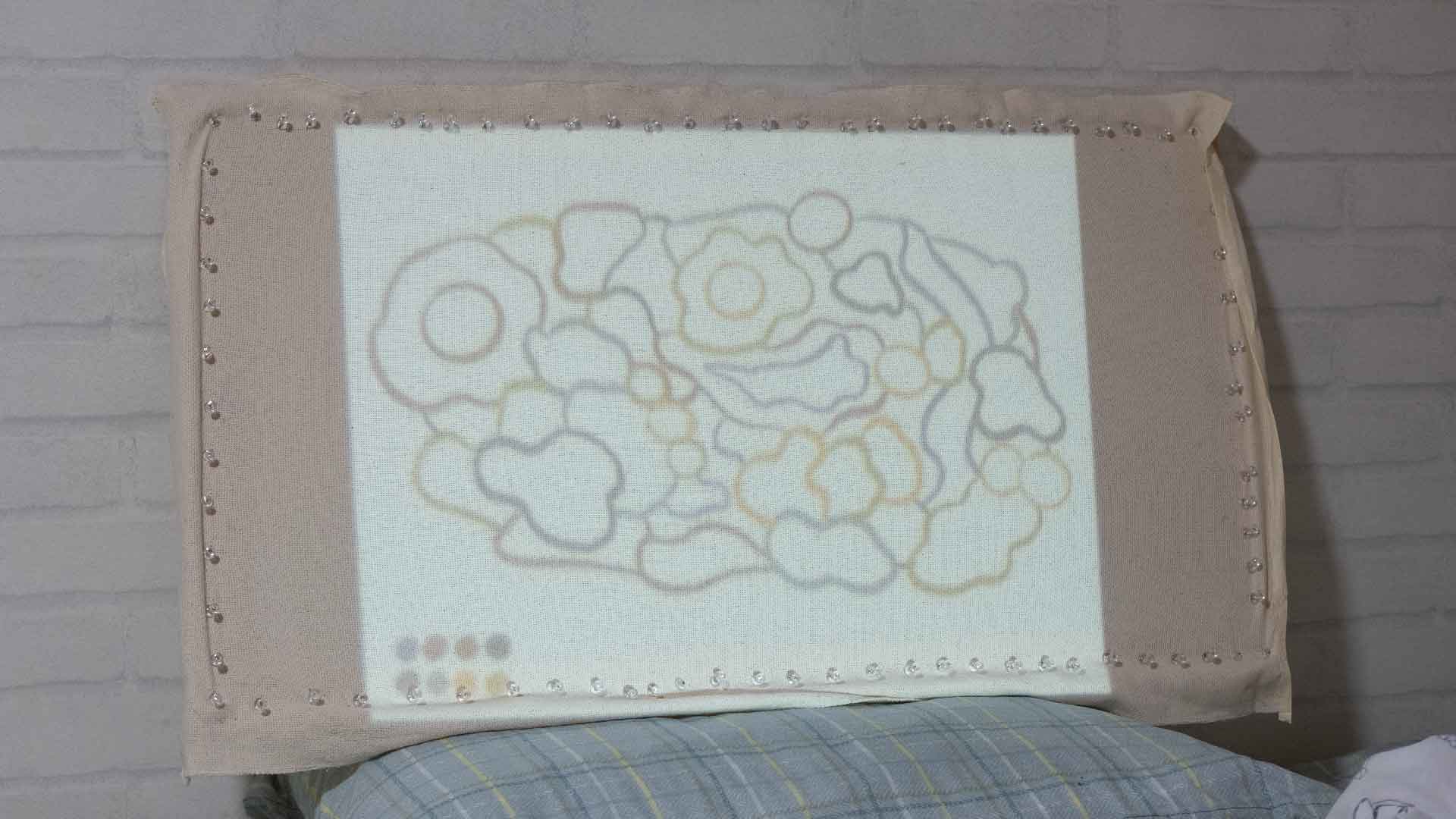

Moss Carpet Version 2

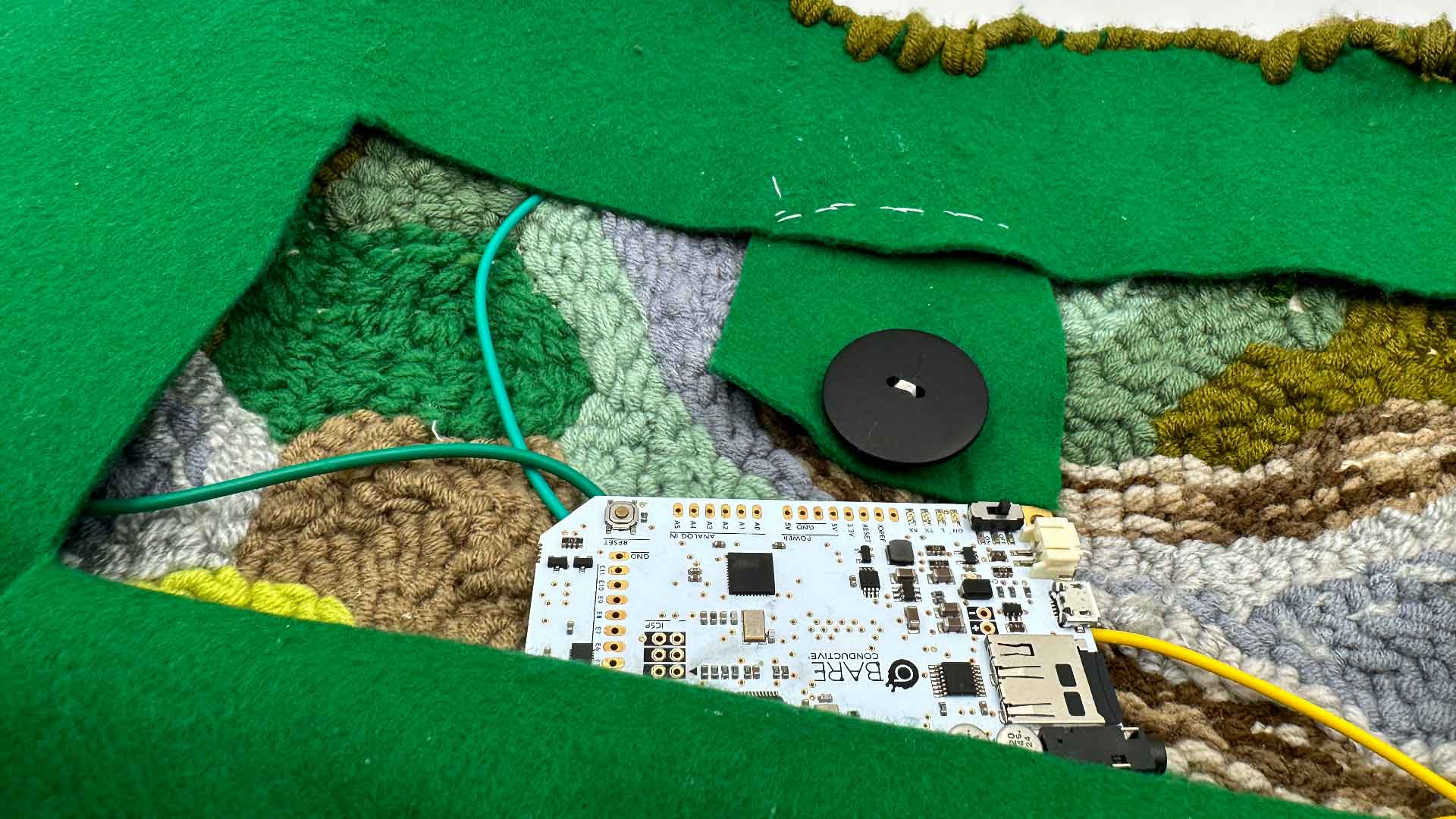

For a second version of the moss carpet, I used a wooden frame to hold the foundation fabric. Once the moss patches had been completed, copper wires and conductive thread were used to connect the sensors. A number of tests were conducted before it was recommended that I extend the connections by sewing more conductive thread around the carpet. For the prototype, the original audio recordings lasted about one minute, which was too long, since no one would have time to listen to eight minutes of recordings during the Open Studio session.

Due to the similarity of the previous audio tracks, it was difficult to differentiate between them. Therefore, I changed the audio tracks and cut them down to three to ten seconds each.

Prototyping Process

Prototype Photos

Refinements for Open Studio Session

As a result of the copper sensors not being responsive when I touched them to play the field recordings, I added a conductive thread. The sensors were easier to locate after the conductive thread had been sewed into the seams. However, I was not able to conceal the thread since it was a sliver in colour and very noticeable when paired with the light green yarn patches. In addition, the wires were easily disconnected since I did not solder them to the touch board, this was solved because the lecturer led a soldering session which made the carpet more durable to use and transport.

Even though the new audio tracks were much better than my first attempt, I felt I could still pay more attention to the sound design after Open Studio concludes.